-

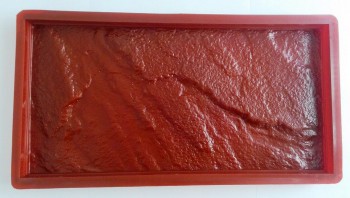

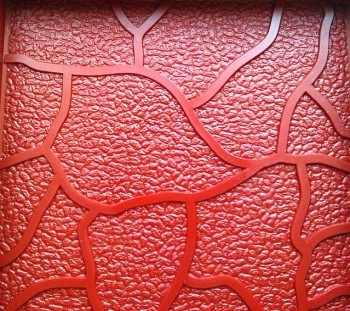

Facing Decor FD-007

Facing Decor FD-007

Carpet Stones FT-040

Border FB-001

Deals-

Parquet FT-020

Parquet FT-020

300х300 FT-304

На верх

300х300 FT-304

На верхBasalt FT-019

Landscape FT-010

Landscape FT-010

Thermo Polyurethane molds for the production of paving tiles and artificial stone

Welcome to the firm Techno-Odis

We are pleased to announce the latest development in the production of decorative concrete and artificial stone - flexible forms of high-strength TPU polyester. Unusually low price for the material in this class - from 90 - $ 100 per sq.m., and incredible strength and performance can produce up to 10,000 fills, are our main achievement.

Thermo molded polyurethane molds for the first time produced industrially using the latest global developments in the field of elastomers. Production of polyurethane molds made on Italian and German equipment.

Our company has many years engaged in the production of artificial stone and paving slabs, so we know about all the problems associated with the operation of the printing process. Molds are an essential component in the manufacture of decorative concrete and gypsum. Their quality is directly related production costs and hence profitability. Depreciation expense on the forms in some cases can be up to 25% of the total cost of the finished product, making the production process in the eternal problem - "the purchase of new forms, instead of the forms out of service" is sometimes after the tenth cycle. And the ability to form accurately transmit the relief of natural stone and all kinds of textures makes finished goods competitive, and it directly affects the final cost.

Cheap plastic molds (25-40 $ per sq m) do not solve the problem for many reasons. Firstly, any transfer of texture can be out of the question due to the technological features of production of these forms. Secondly, because of the desire of producers to offer low-cost goods, used recycled materials or too thin plastic, never intended for the manufacture of such products.In usage of rigid polypropylene forms a common problem is fractions on the finished product in the acute angles, in the process of stripping, plus added additional manufacturing processes for stripping - disbandment vibration tables, steam baths. This entails a rapid failure of such forms, sticking solution, incorrect geometry of finished products - in general, the economy is transformed into continuous losses, additional labor and trouble.